Why Special Alloys?

While 316Lis adequate for most applications, high chloride media, acidic pH levels, high temperature, time of contact, and equipment design can affect the corrosion of stainless steel.

The NEUMO Ehrenberg Group offers a wide range of special alloys: 316L; 1.4435; 904L; AL-6XN®; Ultra 6XN; Hastelloy® C22®/Alloy C22.

These alloys are commonly used in the biotech, pharmaceutical, personal care, home care, food, dairy, and beverage industries worldwide. The main concerns when choosing a special alloy are microbial contamination, system reengineering, maintenance downturns, production loss and safety of its employees and the environment.

Stainless Steel and Corrosion

The uniqueness (secret) behind the corrosion resistance of stainless steel is the formation of a durable and spontaneous ultra-thin film that covers the surface.

As long as the surface is clean and free of contamination, this film protects the steel in a process known as passivation.

The resistance of this film is dependent on the steel grade chosen and the conditions to which it is exposed. If the conditions become aggressive, the oxide film breaks down resulting in corrosion.

The main types of corrosion affecting hygienic and high purity application in aggressive chloride environments are pitting, crevice, and stress corrosion.

Optimum performance is obtained by the use of alloying elements, chromium, molybdenum, nickel, and nitrogen, all of which are very effective in improving corrosion resistance.

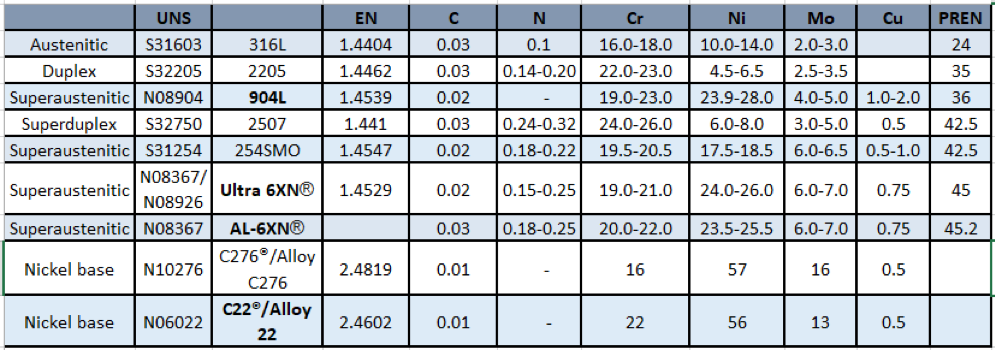

Types of Alloys and PREN

In today’s market there are a wide range of austenitic, superaustenitic, duplex, superduplex, and nickel-base alloys. Besides corrosion performance, other factors should be considered such as commercial availability, appearance, good mechanical properties, and fabrication characteristics.

The higher the PREN-value (Pitting Resistance Equivalent Number), the more resistant the alloy is to localized pitting corrosion by aqueous salt solution.

For stainless steel: PREN = %Cr + 3.3 x %Mo + 16 x %N

Typical Applications

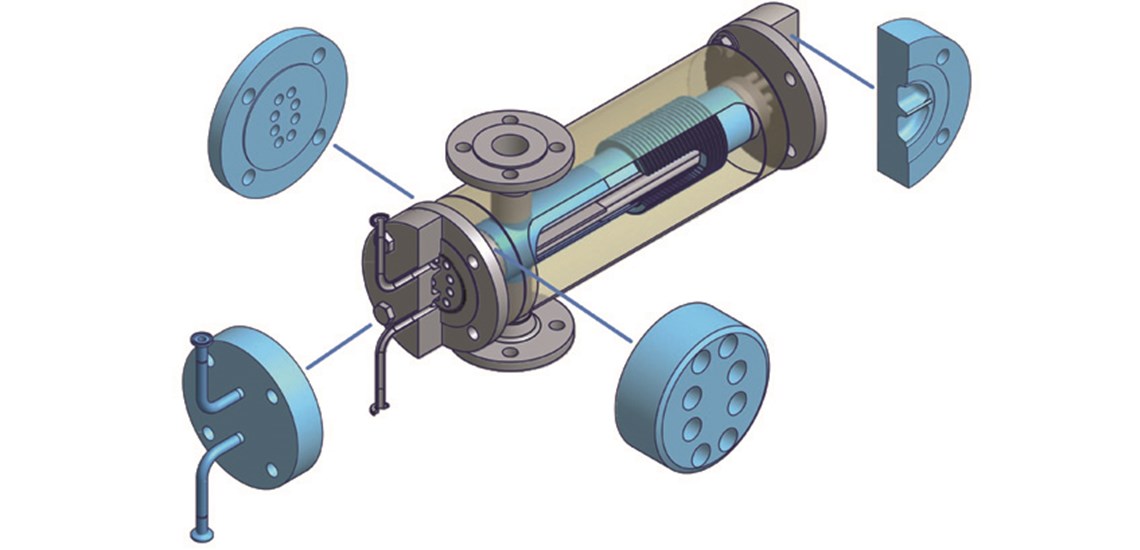

Some of the common applications for the special alloys; 904L/ 1.4539, 6XN/1.4529 and Hastelloy C22®/Alloy C22/2.4602 in the hygienic, biotech and pharmaceutical industries are as follows.

- Biotech and Pharmaceutical: buffer solutions, chromatography lines, API, ethanol distillation, saline solutions

- Personal care: shampoo, conditioner, toothpaste, deodorant/antiperspirant, body wash, liquid soap

- Home care: fabric softener, detergent, cleaners

- Food, dairy and beverage: ketchup, tomato sauce, mayonnaise, soy sauce, barbecue sauce, chili sauce, breaker eggs/liquid eggs, soup, brine solutions, cheese, isotonic drinks

Product Range

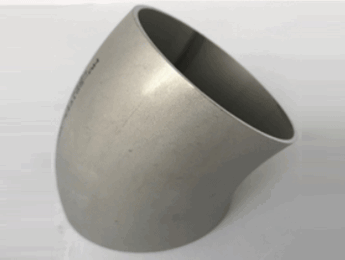

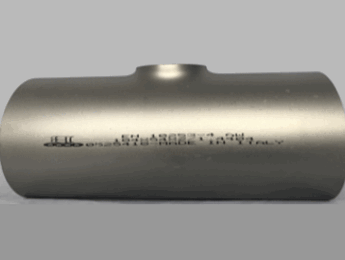

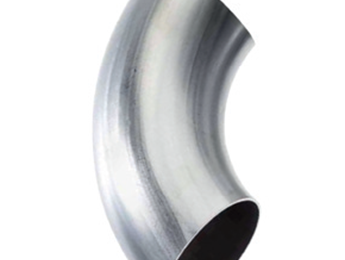

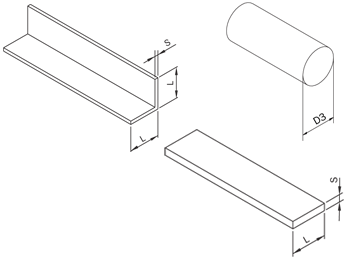

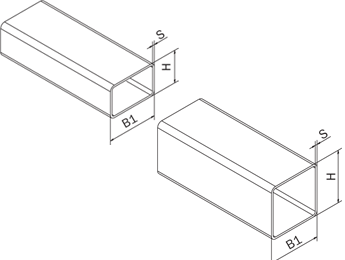

Superaustenitic

The superaustenitic also known as high-performance stainless steel share many characteristics with its standard grade counterpart like high tensile strength, good weldability, and formability becoming a better choice than duplex stainless steel. Additionally, it is a cost-effective alternative to more expensive nickel-base alloys.

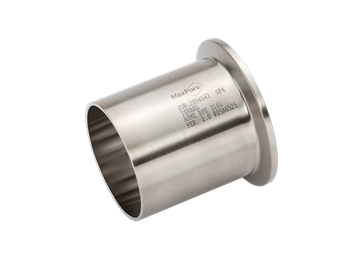

Standard: ASME-BPE

904L, UNS N08904

- Sizes: 1/2” - 4” O.D. tube size

- Internal Surface Finish: SF3 - 0,76 μm (30Ra) & SF4 - 0,38μm (15Ra) EP

- Tube complies with ASTM A249/A269/B674/B677 and ASME SB674/SB677. MTR according EN 10204-3.1

6XN®, UNS N08367

- Sizes: 1/2” - 4” O.D. tube size

- Internal Surface Finish: SF1- 0,51μm (25Ra) & SF5 - 0,51μm (20Ra) EP

- Tube complies with ASTM A270/A249/B676 and ASME SA249/SB676. MTR according EN 10204-3.1

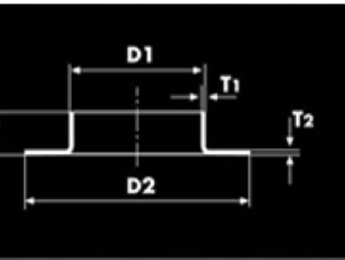

Standard: DIN11866/ DIN 11865 range B

904L, UNS N08904

- Sizes: DN8 (13,5) – DN100 (114,3)

- Internal Surface Finish: H3 (internal Ra < 0,8µm)

- Tube complies with EN10217-7/DIN11866/ AD2000-W2. MTR according EN 10204-3.1

- Delta ferrite content: Max 05% (DF3)

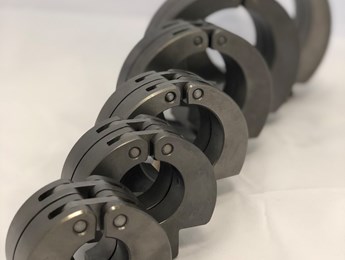

Nickel-based alloy

HASTELLOY Alloy C-22®/ Alloy C22 is a nickel-chromium-molybdenum alloy with enhanced resistance to corrosion. The alloy provides exceptional resistance to pitting and crevice corrosion attacks in chloride-induced media as well as stress corrosion cracking.

Standard: ASME-BPE

Hastelloy® C-22®, Alloy C22, 2.4602, UNS N06022

- Sizes: 1/2” - 4” O.D. tube size

- Internal Surface Finish: SF1 - 0,51μm (20Ra) & SF5 - 0,51μm (20Ra) EP

- Tube complies with ASTM B626/B622 and ASME SB626/SB622. MTR according EN 10204-

Find out more

View / Download more information / technical specification about the MaxCore Special Alloy range.

Made in Germany, used Worldwide

Neumo UK Ltd is 100% owned by AWH (Armaturen Hötensleben) GmbH and stock and distribute AWH products here in the UK.